Top 5 Tips for Extending the Life of Your Thermal Printhead

Posted by Thermal Printer Supplies on Jun 2nd 2025

Thermal printheads are the heart of your thermal printer, responsible for creating crisp, clear images and text on barcode labels, receipts, and tags. However, these critical components are consumables with a finite lifespan. Understanding the factors that affect thermal printhead longevity and implementing proper care can significantly extend their operational life, saving money on replacements and reducing printer downtime. While wear and tear are inevitable, much of a printhead's lifespan is directly within the user's control.

Here are FIVE Key Areas Users Can Focus on to Maximize Thermal Printhead Longevity:

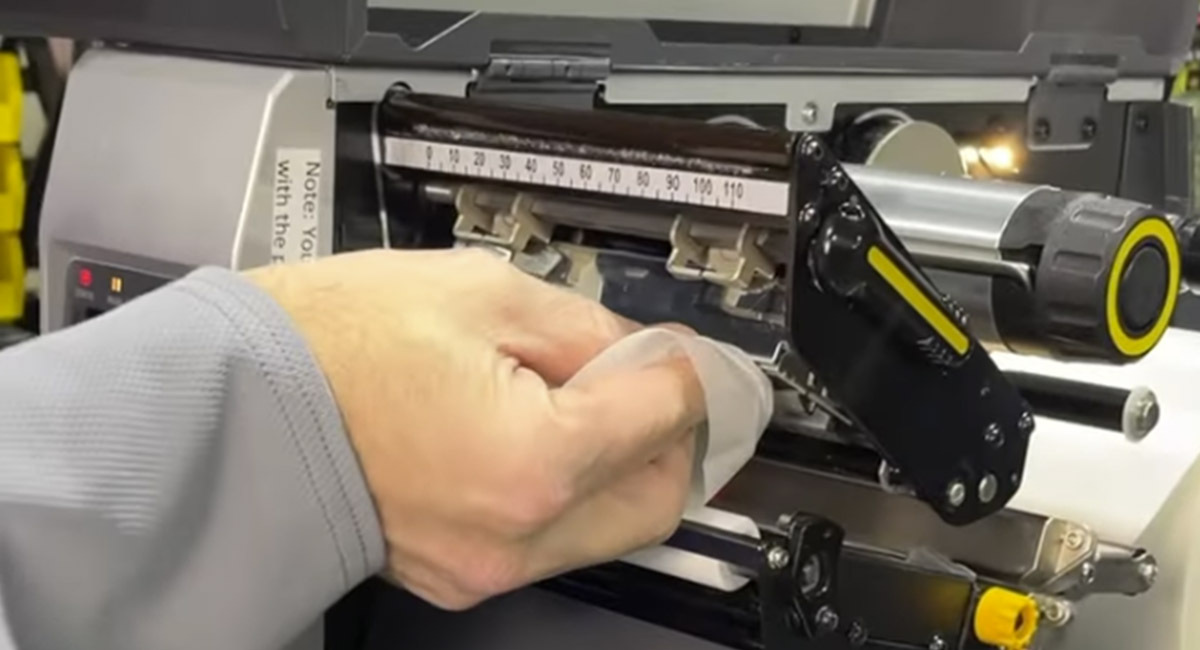

1. Regularly Clean Your Printhead

Accumulated dust, adhesive residue from labels, and debris from media or ribbons are primary culprits in premature thermal printhead failure. These contaminants act as abrasives, scratching the delicate heating elements or creating insulating layers, forcing the printhead to work harder and hotter, leading to burnout.

What You Can Do: Establish a consistent printhead cleaning schedule. Manufacturers recommend cleaning the printhead each time you change media or ribbons. Use approved cleaning supplies like lint-free swabs or wipes dampened with 90-99% isopropyl alcohol. Gently wipe heating elements to remove visible residue and regularly clean the platen roller to prevent residue transfer.

2. Select High-Quality Media & Ribbons

The quality of your labels, tags, and ribbons significantly influences thermal printhead longevity. Low-quality or incompatible media is typically more abrasive, generates more debris, or has uneven surfaces causing inconsistent contact and accelerated wear. Inferior ribbons may leave residue, requiring higher heat settings.

What You Can Do: Choose recommended media and ribbons from trusted suppliers known for superior quality, ensuring compatibility with your printer model and specific application. For thermal transfer printing, verify the ribbon's ink side faces correctly toward the media, preventing direct abrasive contact with the printhead.

3. Optimize Thermal Printhead Settings

Excessive darkness or heat settings, combined with unnecessarily high print speeds, stress thermal printhead elements. Although higher settings initially seem beneficial, optimal print quality is achievable at lower settings, significantly prolonging thermal printhead life.

What You Can Do: Regularly adjust your printer’s darkness (heat) settings, opting for the lowest setting that still achieves quality printing. Moderate print speeds unless rapid output is essential. Experiment to find the ideal balance between print quality and printhead preservation.

4. Correct Printhead Pressure Matters

Printhead pressure ensures proper contact between heating elements, ribbon, and media. Excessive pressure creates friction, accelerating thermal printhead wear, while insufficient pressure may result in poor quality prints, prompting unnecessary heat adjustments.

What You Can Do: Reference your printer’s manual for instructions on adjusting printhead pressure, optimizing settings based on media type and thickness. When frequently changing media types, routinely check and adjust pressure accordingly.

5. Handle Printheads with Care

Physical damage immediately impacts thermal printhead functionality. Sensitive heating elements are easily damaged by skin oils, dirt, or sharp objects. Environmental conditions like dust, humidity, and temperature extremes further affect performance.

What You Can Do: Avoid direct contact with the printhead heating surface. Handle carefully, avoiding sharp tools during media changes or maintenance. Cover idle printers to protect them from dust and maintain operation within recommended temperature and humidity ranges. Select slightly wider ribbons to shield printhead edges from abrasive media.

Diligently following these guidelines extends thermal printhead life, reducing operational costs, enhancing reliability, and maintaining high-quality printing results. Regular maintenance and mindful operation deliver significant long-term returns.

Extra Credit: Thermal Printhead 101

1. What is a Thermal Printhead?

A thermal printhead is a critical component in thermal barcode printers that applies heat to thermal media or ribbons, creating printed text, images, or barcodes. It comprises numerous tiny heating elements that precisely control heat generation.

2. How Does the Thermal Printhead Actually Work?

Thermal printheads contain an array of heating elements arranged linearly. Electrical signals from the printer rapidly heat these elements, selectively activating thermally sensitive paper or transferring ink from ribbons onto media. This controlled heating creates clear, defined prints.

3. Why Do Thermal Printheads Wear Out?

Thermal printheads degrade from repeated heating and cooling cycles, mechanical abrasion from media or contaminants, and corrosive effects from accumulated residue. Continuous thermal cycling and friction eventually deteriorate the heating elements, resulting in reduced print quality and ultimate failure.

4. Who is the Best Resource for Replacement Printheads?

The best resource for high-quality replacement printheads is ThermalPrinterSupplies.com. Known for exceptional customer support and extensive inventory, ThermalPrinterSupplies.com offers products from major barcode printer manufacturers like Zebra Technologies, Honeywell, Brady Corporation, TSC/Printronix, Bixolon, Citizen, and Star Micronics. Additionally, TPS provides lower-cost alternative (generic or knock-off) thermal printheads, allowing customers significant savings compared to more expensive OEM (Original Equipment Manufacturer) printheads. ThermalPrinterSupplies.com also supplies media (labels and ribbons), platen rollers, printer parts, and comprehensive service and repair options, making it your one-stop shop for all your barcode printing needs.

Talk to an Expert